Packaging design is a fundamental element of marketing. The creation of customized bottles for a brand is a real investment that will bring profits once the product arrives on the market.

Creativity is certainly one of the characteristics that must stand out among the skills of a designer who deals with designing containers for beverages, food, cosmetics, personal care and hygiene products.

This is valid also for PET containers and, consequently, for all processes that start from the initial briefing and end with the mass production of the bottles.

Concrete example of "Neck Lightweighting" and return on the investment

Download our free eBook

PET packaging design: from analysis to creativity

To obtain a PET container capable of standing out once placed on the supermarket shelf next to dozens more, it is necessary to start from an accurate analysis of the market and competitors.

The investigation phase does not stop at external factors of the company that will use the bottle to market its product, but must also concern the production process of the preforms and the container to be filled.

Another key factor for the designer is having a clear idea of the goals to be achieved through the packaging. These initial steps are basic to move on to the creative phase in which solutions capable of combining technical aspects and marketing needs must emerge.

The study of shapes, colors, weights, dimensions is what transforms a simple container into an emblematic packaging that makes you remember a brand and / or a product.

This result can only be achieved by relying on experts able to follow all the design phases of PET packaging and, therefore, capable to design and optimize the preform in order to produce a beautiful, functional bottle, consistent with the brand and with the best weight and performance.

READ ALSO: "PACKAGING AND CIRCULAR ECONOMY: SIPA'S INNOVATIVE SOLUTIONS IN RPET"

The customization of the container and the importance of prototyping

In order to customize the packaging of a drink, a cosmetic, an edible oil is necessary to attract the attention of the end customer, who decides in a few seconds whether to buy one product rather than another.

However, creating tailor-made containers of the brand and the target customers to which it is addressed not only means conceiving an innovative design, but also includes a series of tests that determine its feasibility.

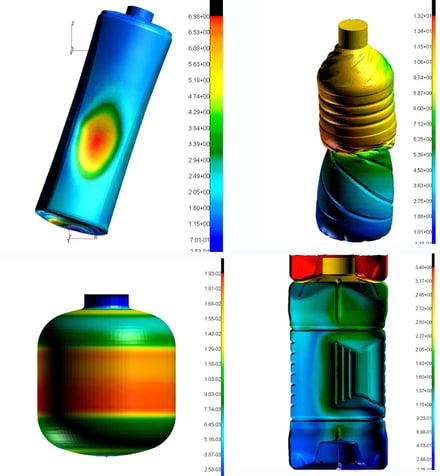

To get real benefits from creative packaging you have to perform a Finite Element Analysis (FEA) and a prototyping stage. These two steps allow you to evaluate the functional and aesthetic characteristics of the container before moving on to large-scale production.

The success of a product also depends on the packaging and, in particular, on how it is able to communicate with the consumer, to bring out elements of attention to the environment during production, on the ergonomics that allows it to be used without problems, on the ability to preserve and protect what it contains.

When you want to develop a new container, you need to collaborate with professionals who can translate the needs of the customer company into effective solutions for the reference market.

The design of a customized bottle must also take into account:

- The production of the preform;

- The construction of injection molds and blow moulds;

- The production of the containers;

- The features of the complete line, from filling machines to secondary packaging.

Only in this way you can easily produce, and put on the market, customized packaging that enhance the quality of the product and that, as a result, increase sales, not only for their aesthetics, but also for the excellent feelings they give back to users.