At the present time, sustainability is the foundation of the strategies of development of all those enterprises that keep a watchful eye on the future.

SIPA, in its role of leadership in the sector of PET packaging, has devoted considerable investments to innovations, in particular in the study of solutions for the reduction of the weight of bottles and preforms in PET.

The goals of these technological advances are different, though closely linked: manufacturing cost reductions and environmental concerns, reflected in social responsible choices.

At the level of the global market, the idea of reducing the weight of packaging, while maintaining the strength of the package, began many years ago.

The targets initially reached by the companies seemed exceptional, impossible to improve further.

However, thanks to SIPA’s research and development laboratories, we were able to arrive at new and exclusive steps forward, which had been practically unthinkable until then.

READ ALSO: "MARKET TRENDS FROM REUSING TO LIGHTWEIGHTING OF PET BOTTLES"

Examples of weight reduction achieved by SIPA

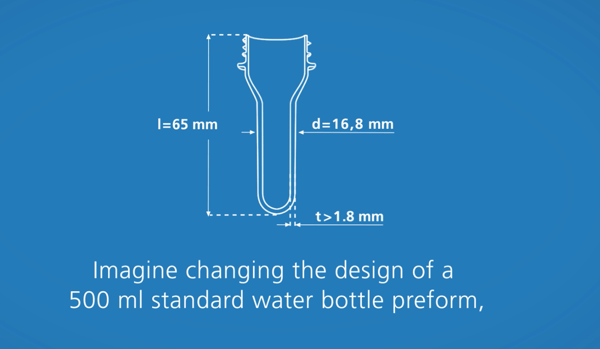

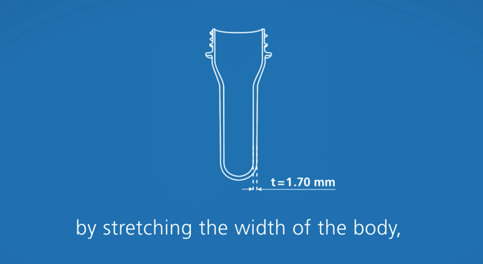

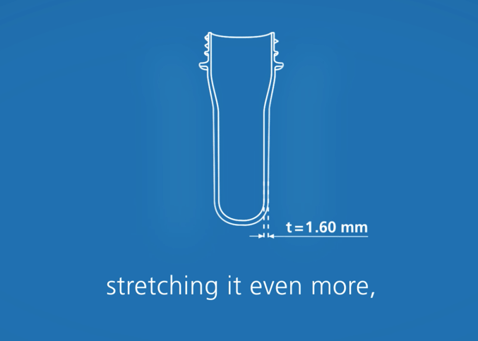

Let’s take the example of 500 ml bottle preforms with their innovative design stretching the width of the body, first with t = 1.70 and later arriving even at 1.60 mm.

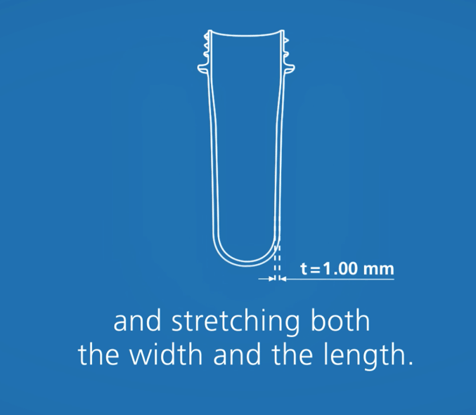

A process that led to increasing both the width and the length of the preforms,

improving the distribution of the material forming the bottle.

The most significant results concern the reduction of the thickness under the neck of the bottle, on the walls and on the base.

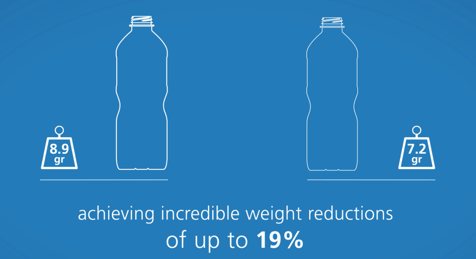

The overall weight reduction thus obtained was extraordinary, lighter by 19% .

The process also safeguards both the quality and the performance of the standard bottles.

Eco-packaging: advantages for everyone

What are the advantages for everyone, from the producers to the end consumers?

-

Less raw material consumed

-

Less waste

-

Lowering transportation costs

-

Reduction of the carbon footprint

Reduction of the weight per package of shipments of preforms in PET

The injection-compression technology underlying the XTREME installation produced by SIPA is a definite step in the direction of reduction of the reference material in the base, body and shoulders of preforms in PET.

To design a lighter neck, however, a detailed study of the product is necessary along the entire processing chain.

This target requires a holistic approach that takes account of the production of the preform and of the bottle, as well as their handling in the filling stage and the strength of the packaging.

Here are a few of the elements that SIPA assesses in the design of a new lighter neck:

-

Function along the entire line and the possibility of reducing the need to alter the configuration of the utilities for production of the bottle, in addition to the existing filling function.

-

Reduction of the alterations necessary to the existing injection molds.

-

Functionality of the neck during filling.

-

Possibility of increasing the potential for weight reduction, using special treatments on the surface of the molds.

Once all these assessments have been made, it is possible to perform internal tests to launch the new neck.

Weight reduction of neck for HEXALITE by Bericap

Here is a brief example of how this process was put into practice successfully: SIPA has applied an idea for improvement of the neck for Bericap caps, creating a preform with a new narrower neck for the 26 mm caps of the HEXALITE line by Bericap.

The new neck is - incredibly - 23% lighter than the original.

The producers of preforms with this new neck can now reduce their consumption of PET, without jeopardizing the performance of the container.

Moreover, no alterations are needed to the existing peripheral preform handling mechanisms.