It is always the market that dictates the rules and has long told PET packaging manufacturers and users to reduce the weight.

Today every detail must be studied to use the least amount of material possible while ensuring compliance with technical parameters that describe the quality, for example, of a water bottle or one for carbonated drinks.

Let's see why it is important to intervene on the neck of the PET preform to obtain packaging in line with trends.

Light weighting PET bottles: benefits for the environment and business

The reduction of the amount of plastic is now a clear principle both to professionals and to end consumers who purchase products contained in packaging made with this material.

In addition to the use of raw material from recycling, the light-weighting of PET preforms is an important step for companies that want to reduce the environmental impact of their industrial processes.

Every gram of PET that is saved results in an ecological, but also economic, advantage. This is evident with the millions of bottles produced every month by a single company to meet the demands.

These benefits are only real if the lightened packaging continues to be resistant, ergonomic and suitable for customization and adapting to marketing operations.

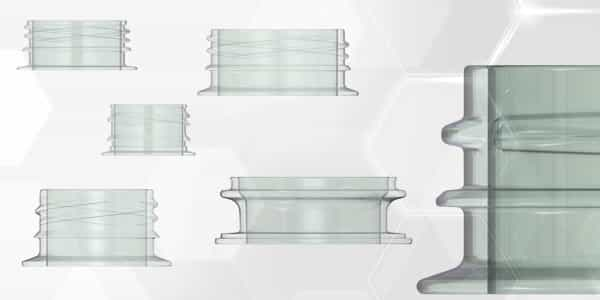

A detail that makes the difference: the light weighting of the PET bottle neck.

To understand the importance of reducing the weight of bottle necks, it is necessary to start from a deadline dictated by the SUP (Single Use Plastics) Directive: from July 3rd, 2024 plastic beverage containers can only be placed on the market if the caps and lids remain attached to the containers during the intended use phase of the products.

In the few years that separate us from this turning point the attention on the closures of beverage containers up to 3 liters brings with it the opportunity to optimize also the weight of the necks without affecting their functionality.

Key characteristics that light-weighted necks must preserve are:

- Same performance of original neck finish

- Same closures

- Same handling

- Only neck ring change

- No modifications of functional areas

- No closures performance difference

You should not believe that this operation leads to minimal improvements, because, on the contrary, it is possible to achieve objectives of lightening packages ranging from 16% (PCO 1810 conversion 5g - PCO 1810 light 4.2g) to 52.6% (PCO 1881 conversion – GME 30.37).

Which necks can be light-weighted?

The scope of neck light weighting of packages is very wide and, therefore, many companies can obtain economic and ecological advantages from this optimization

The categories of PET containers on which you can intervene by light weighting the packages are:

- Mineral water bottles

- Dispensers

- Carbonated Soft Drink bottles

- Juices, isotonics, RTD tea hot fill bottles

- Edible oil bottles

To obtain benefits from this process of improvement it is not necessary to change entire preform and bottle production equipment, but in most cases, it is enough to change only the neck ring.

It is the right time to invest in the light weighting of necks to follow the ecological evolution of the market and, above all, because of the rapid return on investment that guarantees gains in a few months.