The New Machinery Regulation 2023/1230, published in the Official Journal of the European Union on 29 June 2023, came into force on 19 July 2023 in all EU countries.

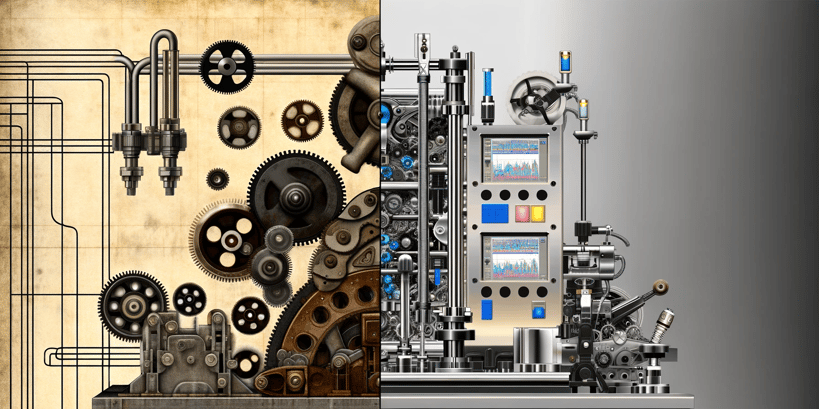

Its function? That of gradually replacing the existing legislation, i.e. the Machinery Directive 2006/42/EC, which is expected to be completely repealed as of 20 January 2027.

What the Machinery Directive provided for

The 2006 Machinery Directive establishes the rules relating to safety on many types of industrial systems, with particular implications also on the management of machinery and the maintenance of packaging production lines.

The Directive, as a whole, provides a legislative framework aimed at ensuring that industrial machinery is designed, built, operated and maintained in a safe manner.

The key points of Directive 2006/42/EC

There are several focal points of the Machinery Directive that concern the management and maintenance of packaging plants, in particular:

Safe Design: The directive requires that machines have to be designed with the aim of ensuring maximum safety for operators and other persons involved in their use. The design should prevent health and safety hazards while minimizing mechanical, electrical, thermal, and chemical hazards.

Technical Documentation: Manufacturers are required to provide detailed technical documentation for each machine or plant. This documentation should include instructions for safe use, maintenance information, technical diagrams, and compliance documentation.

Risk Assessment: Before commissioning a plant, company representatives must conduct a risk assessment to identify and address potential hazards. This assessment is intended to help establish appropriate security measures.

Labelling: Packaging machinery and equipment must be clearly and legibly identifiable with information about the manufacturer, serial number, safety instructions and restrictions on use.

Operator Training: Operators must receive the necessary training to safely operate individual machines or systems. The training covers the proper use of the machines, safety measures and emergency procedures.

Harmonized Standards: The Directive refers to harmonized standards, i.e. technical standards recognized at European level. Compliance with these standards can be used to demonstrate compliance with the Directive.

Corrective Maintenance: In the event of breakdowns or problems of various types, it is essential to perform corrective maintenance in a timely manner to restore the safety and efficiency of the system.

Periodic Maintenance: Packaging plants must undergo periodic maintenance to ensure that they continue to operate safely and efficiently. Maintenance must be carried out by qualified personnel and recorded in specific documentation.

Regulatory Updates: Plant operators must stay informed about regulatory changes and make necessary updates to machines to keep them compliant with current legislation.

The New Machinery Regulation 2023/1230

The new Regulation emphasizes the importance of ensuring the safety of machinery from the design and construction phases, with the aim of reducing the social cost due to accidents caused by the use of the systems.

Key objectives include increasing the safety of single machines, human-machine collaboration and the use of Artificial Intelligence systems within industrial machinery.

The Regulation also aims to simplify administrative burdens through the digitisation of documents, promote legal certainty, and ensure more effective market surveillance at European level.

Modification to existing machinery or plant

With regard to modifications to machinery, the Regulation lays down a specific definition of "substantial modification".

A modification is considered substantial if it is made after the product has been placed on the market or put into service. Since a machinery intervention has the potential to create new hazards or increase risk factors, any substantial change must be followed by a new certification of the machine.

The new legislation also highlights the importance of relying on qualified parties for safety adaptation interventions and the potential risk associated with adding software to the safety control system.

The Regulation entered into force on 19 July 2023, but will be applied from 20 January 2027, with some exceptions.

Until this date, the machines must comply with the requirements of Directive 2006/42/EC. From 20 January 2027, machines and systems will have to comply with the requirements of Regulation 2023/1230 and be accompanied by an EU declaration of conformity.