As we know, drinking yoghurt is one of the most widespread and performing products currently present on the milk and dairy market.

Shops, mass retail and on-line shops offer a particularly varied range of this type of product, sub-divided into various categories and sub-categories, which are distinguishable firstly by three milk macro-types: probiotic cultures and non-probiotic cultures.

Rules on production vary from Country to Country. Under Italian law, the term “yoghurt” can only refer to milk that is fermented with live and living cultures, provided this has a cell density equal to or higher than ten million cells (as colony-forming units) per millilitre of product.

However there are also other products obtained from different types of milk or different cultures, that can be valid alternatives both from a nutritional and from a commercial viewpoint, satisfying a specific range of consumers.

Differences between drinking yoghurt and eating yoghurt and production phases

At composition level the yoghurt drink is very different from the more traditional creamy yoghurt that is eaten with a spoon.

At composition level the yoghurt drink is very different from the more traditional creamy yoghurt that is eaten with a spoon.

What changes is the ingredient evaporation and concentration phase.

As regards the yoghurt drink, preparation is aimed at not giving body to the end product, by using skimmed milk with the addition of water.

Another difference relates to the various phases, starting with fermentation.

For drinking yoghurt this phase almost always takes place at higher temperatures than those used for creamy yoghurt.

This encourages the growth of specific microbiological strains, which are able to produce large amounts of lactic acid. Lactic acid is the compound required to reach very low pH values, essential for this type of product.

The phase following fermentation involves other unique characteristics: the coagulated mass must be cooled and stirred continuously (at industrial level the product is homogenised at very low pressures), unlike creamy yoghurt, which requires the least possible stress.

When production of the drinking yoghurt is complete it moves on to the “flavouring” phase, adding the flavours that the individual manufacturer wants in the range.

The market provides an innumerable choice of flavours, using semi-processed fruit purées.

It must be remembered that drinking yoghurt is a product that is substantially aimed at a young market, including a large percentage of children, so strawberry, banana and vanilla are among the most frequently requested flavours.

Natural yoghurt drinks, on the other hand, have only a marginal position.

The rules for proper packaging

The shelf-life of yoghurt drinks is similar to that of creamy yoghurt: approximately 30 days. It is extremely important to take care not to contaminate the product during packaging.

This is because yoghurt drink is a product that is easy to make but, at the same time, has a high microbiological risk potential.

All production and packaging phases must be planned with care in order to keep under control all the critical phases in processing and maintenance of the product.

In particular, it is necessary to:

- Carry out processing in an environment that is as far as possible free from microbiological pollution;

- Reach the bottle closing phase as quickly as possible after filling, so as to limit as much as possible any microbiological contamination;

- Maintain the cold chain, storing the product at 4 °C.

Technical Study: "All the advantages of integrated bottling lines in the PET sector"

The most effective packaging procedures to optimise the process

It is undoubtedly true that the ideal system for packaging of delicate products such as drinking yoghurt is one made up of machines that are able to provide an intrinsically clean environment.

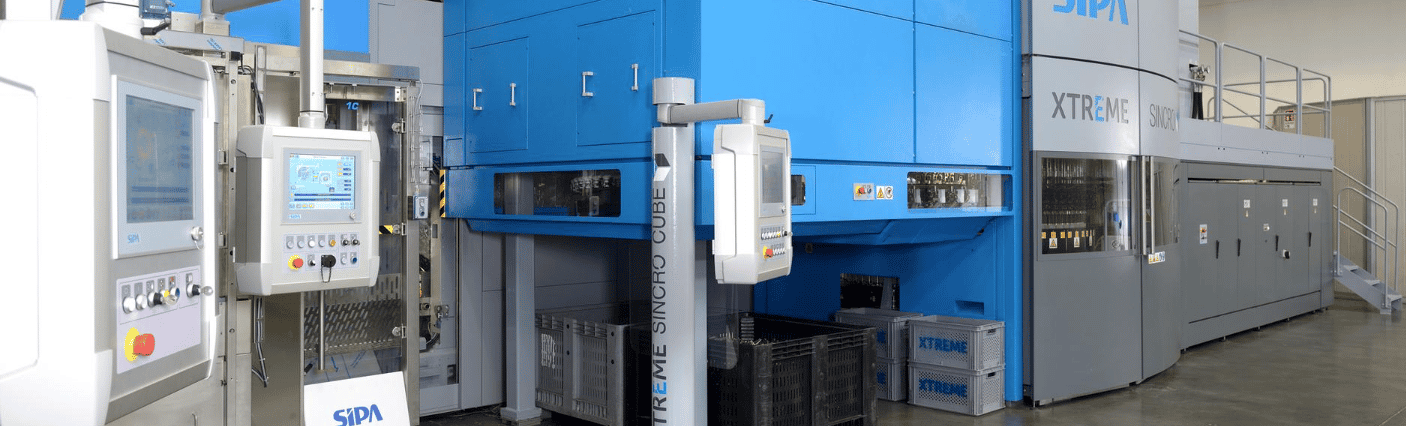

The most innovative solutions, in the context of liquid packaging, are therefore lines such as Xtreme Sincro Cube from SIPA, which consists of a rotary platform for the high output and high efficiency production of preforms, directly connected to a blower and a filler.

A single plant that starts from granulate and finishes with a filled and capped bottle, in an extremely clean environment.

Xtreme Sincro Cube streamlines the production process: eliminating preform cooling and preform heating units, preforms storage and transportation.

The process from PET granules to filled bottles in one-step means major resource savings such as energy, space and manpower.

Additional characteristics relate to:

- Freedom to design and produce preforms that are up to 8% lighter than traditional injection moulding

- No preforms cooling and reheating thus saving approx. 25% of energy

- Clean system, no hydraulics (another important aspect for the cleanliness of the environment)

- Reduced footprint (-50% vs. traditional plant)

- 100% quality inspection (preform in line quality check)

- Quick changeover(1 minute per cavity)