PET can be recovered, and the material reused, through a series of special washing processes or by a chemical treatment to break down the PET into its raw materials or intermediates, which are then purified and, typically, converted into new PET resin.

According to market data, it is clear that the industrial bottling sector is moving towards a massive use of recycled PET (r-PET) for numerous types of products, including edible oil.

Production advantages are varied and particularly concern environmental sustainability and savings in energy costs.

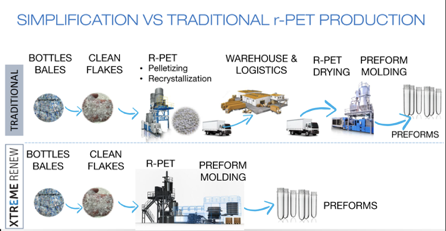

Process steps of traditional system for PET moulding machine

Usually, the systems producing r-PET (recycled PET pellets instead of virgin PET) are composed of the following steps:

- Acquiring used PET packaging,

- selecting packaging and transforming into flakes,

- flakes washing,

- pre-drying,

- removing residual internal and external moisture,

- decontamination,

- IV increase and stabilization,

- extrusion,

- filtering extruded material,

- producing cylindrical or spherical pellets

One of the different aspects to consider is decontamination and moisture removal from the material to be treated and the increase of intrinsic viscosity.

PET packaging recycling systems include a vacuum reactor which is connected directly to a single-screw extruder. Mixers have the task of decontaminating and pre-drying PET material and of increasing intrinsic viscosity.

R-PET recrystallized pellets are put in bags, stored in special companies and finally distributed to packaging companies.

Arriving at the factory where the preforms will be produced, the r-PET granules must be dried again, then melted in the extruder, and then injected into the mould for preforms production.

How the most modern PET moulding machine works: the Xtreme RENEW system generates 30% energy savings

An extremely avant-garde system, such as Xtreme RENEW by Sipa, revolutionizes this procedure by simplifying it.

Once the melt has been filtered, it is conveyed directly to the system to produce the preforms in a single heat cycle.

Recrystallization is not required, but even before that, palletising is not necessary for pellets cooling, which will then be dried and plasticized again at high temperatures.

The containers made with recycled PET starting directly from flakes in a single thermal cycle increase the number of possible recycling because they avoid double extrusion, while avoiding the excessive PET yellowing.

By producing the preforms directly from the decontaminated and filtered melt, the three traditional steps are skipped, saving 30% of total electricity compared to the traditional process where the recrystallized pellets are then dried in a dryer for 6 hours, melted at 280° C and processed then in preforms.

This saves around 0.25 kW/kg of PET.

All Xtreme RENEW advantages: 1.44 million KWh saved in a year

In a nutshell, the recycled PET packaging produced by Xtreme RENEW offers:

- Simplifying process, through removing granulation and recrystallization steps, logistics associated with storage and granules distribution, granules drying and the second extrusion.

- Direct switch from flakes to preform, in a single heat cycle, with savings about 30% of energy costs.

- A lower TCO up to 15%, considering that flakes cost is lower than virgin material for PET, and much lower than the r-PET

- More than 20% of space gained in production environment.

The total energy saved, considering a traditional 1000 kg/h system for 8000 yearly productive hours, is 1.44 million KWh per year.