When you think about the design of a large size for water packaging you imagine that functionality has a much more relevant role than creativity, but this is not always the case.

Large size water packaging, compared to bottles, may have less need for marketing-oriented design operations, but they often need creativity to solve functional problems related to logistics and handling by the end customer.

Let's see two ideas that make the difference in the packaging design of large-size PET containers for water.

Idea to simplify the lifting of PET large size water packaging: the handles

One of the main difficulties that a consumer finds when he has to install the filled container on the water dispenser in the house or in the office is to lift it as comfortably as possible.

To overcome this problem you can create PET packaging with side handles or under neck ring handles.

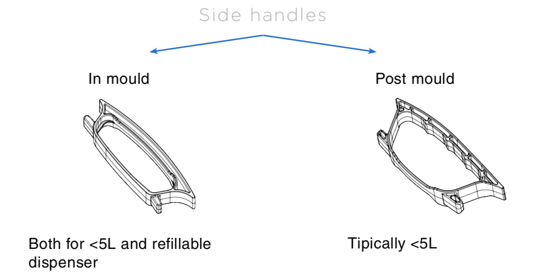

For the first solution, there are two subcategories with specific characteristics to choose from:

- Side handles - In Mould, both for <5L and refillable dispenser

- Side handles - Post Mould, typically <5L dispenser

Under neck ring handles, on the other hand, are used for water containers with a capacity of less than 5L.

During the design of these functional elements, you have to consider all the characteristics that guarantee their robustness and a safe anchorage to the packaging, but also all the stylistic details that make the handles beautiful design elements to look at and touch.

The style, ergonomics, texture of the handle are factors that can convince a person to buy the large size water packaging of the brand that has also paid attention to this detail.

Collapsible dispenser: large size containers more hygienic and recyclable

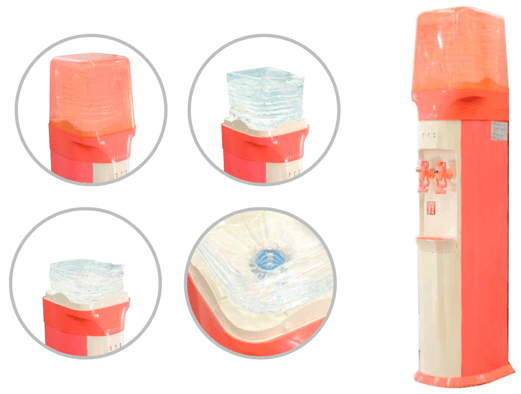

SIPA has taken care of the design of collapsible dispensers for two Japanese companies specialized in the delivery to home and office of large water bottles.

In this case, the creativity of the designers has combined with technicians’ know-how to conceive a packaging that does not let the air in during the water supply and that, consequently, blocks the transport of bacteria inside the water dispenser bottle.

SIPA, in collaboration with Itochu Machine-Technos Corporation (a company specialized in the import and engineering of equipment), has created two differentiated packaging, one for each company, but both with thin walls and special ribs that determine its controlled collapse during water supply.

The final effect is a compacted packaging that is very easy to transport and to handle into the PET recycling system.

When designing a large-size, transparent, thin and square-shaped bottles, the designer has to avoid crystallization of the corners, resulting in the appearance of white areas, perfectly controlling the production process.

The two Japanese companies now use SIPA SFL 2/2 linear stretch-blow moulding machines that guarantee high productivity, high packaging quality and a simple and stable blow moulding process.