Many companies feel the need to obtain aesthetically perfect bottles.

As a consequence, handling of the preforms in the machines making up the line must be minimal, essential and carried out with the greatest possible precision.

In this case, SIPA has the perfect integrable solution for this specific need.

What is SIPA’s solution?

Being a company that was born in the automation sector, SIPA has a solution that is unique to the market of PET bottling production lines: the ability to integrate a traditional technology preform production machine with a linear blowing machine.

This is thanks to technology that allows solutions capable of optimising processes more and more, using progressively more reliable machines.

How integration takes place

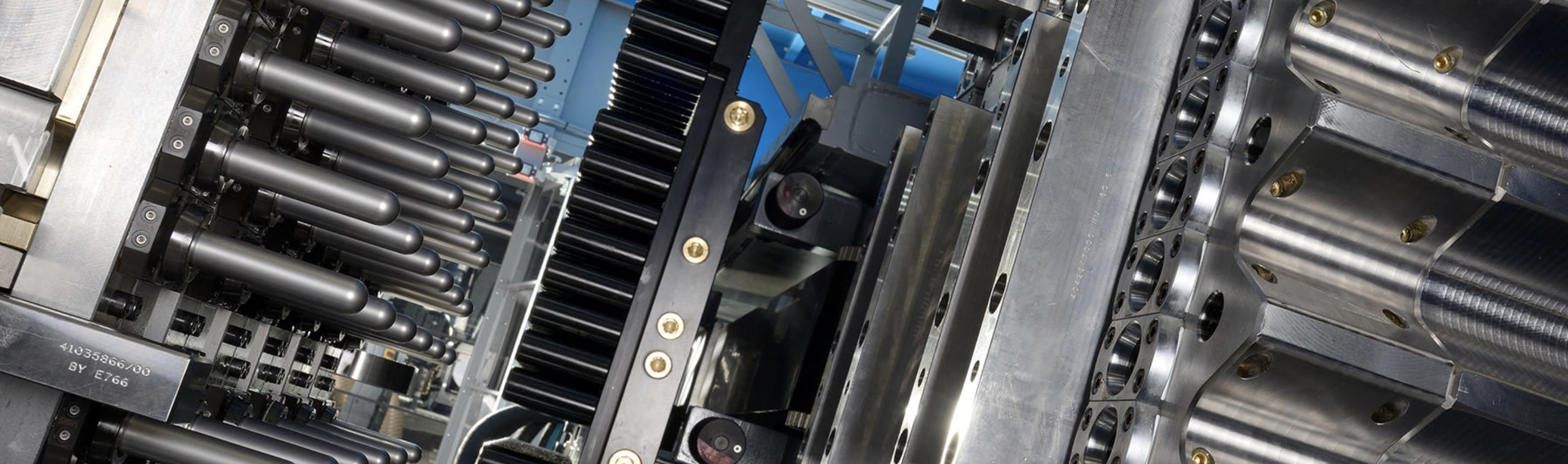

The two machines that can be integrated are: fourth generation XForm and the SFL linear blower.

Between the two SIPA machines it is possible to insert a specially designed robotic application. The machine is able to take the preforms coming out of the XFORM and load them into the linear blower feeding system.

In this way it is possible to have perfect bottles for all those cases in which maximum aesthetic attention to detail is required, to the advantage of production quality.

Sipa has many years’ experience in the robotic handling of various types of loose containers, boxes and cartons, guaranteeing maximum reliability and precision even in the most complex movements.

The characteristics of latest generation XFORM machines

The following are further details regarding production of the preforms. The XFORM GEN2 XP system, by SIPA, incorporates latest generation technology for the production of preforms. The system provides numerous benefits in a single solution: speed, flexibility and ease of use, and the lowest conversion cost on the market.

The new technology integrated in the 250, 350 and 500 ton systems, capable of fitting 96, 128 and 180 cavity moulds, respectively, has also been designed to manage the most complex applications. It offers fast cycle times and leading energy efficiency levels for the sector, combined with the lowest maintenance costs ever.

A further advantage: like the other XFORM systems, the GEN4 XP accepts practically all the injection moulds produced by the main manufacturers.

Technical Update: "Latest generation of PET preform injection molding machine: XFORM"

SIPA’s SFL linear blower: the most flexible system on the market

SIPA linear blowers are an extremely flexible option, without paragon on the market.

This is because, over the course of the last 25 years, SIPA has gained vast experience in the development and optimisation of bottles and preforms, designing thousands of containers for a multitude of applications, from beverages to food products, cosmetics, detergents, pharmaceutical products.

SIPA is able to support its customers, offering the preform and container best suited to their specific needs, from the design and supply of samples all the way to quality certification.

Furthermore, the company is able to guarantee functionality and optimisation of the packaging as a whole: preform, container, seal, label, packing and pallet forming.

Technical Update: "SFL, SIPA’s PET blow moulding machine: excellence and flexibility"

PET containers with extremely customised forms

The innovative SFL linear blowing system provides great flexibility in the production of the widest range of container types.

The SFL range can produce standard and customised containers for standard and hot filling, oval bottles with shaped neck and multi-layer bottles, light-weight bottles, small containers for the pharmaceutical industry, and also large containers of up to 30 litres, all this with high production capacities.

It is only a great push towards innovation and the tendency to explore ever new paths, together with the skills of a single preform production, blowing and robotic handling company, that has allowed this innovative solution to be created.

A configuration that is outside the box and has never been created before, but that allows the achievement of previously unimaginable results and advantages.

Want to find out details of all the SIPA options available for your Company?