SIPA’s Xtreme Renew di SIPA is the first circular system in the world that produces preforms and bottles while saving the environment, energy and money.

SIPA, in partnership with EREMA, has developed XTREME RENEW, the first technology in the world to produce PREFORMS from 100% r-PET washed FLAKES in a single energy cycle.

An environment-saving and cost reducing technology, this revolutionary “bottle-to-bottle” system was designed for the circular economy: XTREME RENEW uses fewer raw material (-10%), saves more energy (-30%), has a low TCO (-15%) and reduces logistic cost (-20%) compared to any other technology.

Xtreme Renew main advantages

- Production of preforms containing up to 100% rPET from simply washed flake to food-grade PET with virgin-like quality

- Major process simplification

- Safe and approved process (FDA, Efsa, Invima, Anvisa, …)

- Top preform quality: IV stability, top colour values, clear preforms, food-contact compliant

- Sustainable process, from waste to resources

- Up to 15% lower TCO (Total Cost of Ownership) vs. traditional recycling concept

- Major energy savings (30%) vs. traditional recycling concept

- Up to 20% reduction in logistics/warehouse vs. traditional recycling concept

Read Also: "From used to new 100% rPET bottles: SIPA Xtreme Renew"

Main features of the decontamination process

One of the key benefits of the patented VACUREMA® technology from EREMA is that decontamination and the removal of moisture already takes place BEFORE the extrusion.

This is a clear bonus for the quality of the melt and, as a result, of the end product, because IV values are very stable as a guarantee of top mechanical properties of the finished product.

The key components of the system include a vacuum reactor which is connected directly to a single-screw extruder.

Thanks to the ingenious function of the mixers in the vacuum reactor they feature three ultra-efficient function zones which interact perfectly with each other to decontaminate and predry the PET material.

Extrusion process

With very low residual moisture the clean, perfectly prepared PET material enters the intake zone of the extruder.

This material transfer takes place under high vacuum. As a result, no additional degassing ports are required on the extruder.

This means that VACUREMA® technology drastically reduces the length of the extruder, lowers its energy consumption, improves the colour values (b value) of the processed material and keeps AA values to low level.

Moreover, the strong homogenisation performance of the extruder plays a significant part in turning the different input IV values into a stable output IV value.

Filtration process

In the downstream large-area high-performance fine filter, the material is filtered with a mesh screen width of 25 – 62 µm (typically with 40 µm, depending on the end application: CSD, water, etc.)

The filter system is equipped with a patented fully automatic self-cleaning system that enables long filter service life.

The melt is now ready and can be transferred directly to the downstream unit.

Rotary injection-compression process

Rotary molding wheel:

- Modular design of the wheel and of the press module

- Reduced cavity tonnage for reduced mold wear (max 2 ton)

- Mold safety: intrinsic protection; each mold can be remain open

- Easy maintenance: each module press can be fast removed (20 minutes per station)

- The use of single cavity dosimeter allows the simultaneous production of 2 different preforms

- Preforms exit aligned, so can be sorted in different bins

Preforms post-mold cooling process

Cooling is made with cold air at high speed on external and internal surface of the preform.

There is no need to change the personalization parts since grippers are self-adjastable.

Read Also: "Preform line products: XTREME Renew from flakes"

Xtreme Renew applications

XTREME RENEW produce a wide range of light weighted food-grade preforms with up to 100% r-PET starting from simply washed flakes for a wide range of applications: mineral water, juices, RTD tea, milk, edible oil, etc.

Talking about Xtreme and SIPA: winners of World Star Packaging Award

European technology that makes it possible to produce PET bottles entirely out of post-consumer waste has been recognized with a prestigious WorldStar Packaging Award at a gala ceremony hosted by the World Packaging Organisation (WPO) in Prague, Czech Republic.

The WPO presents World Star Packaging Awards every year to what are considered by independent experts to be the best packaging solutions and applied technological innovations.

XTREME Renew technology is unique in the world in its ability to produce bottles, suitable for food contact and with properties as good as those of bottles produced from virgin PET, directly from flakes of post-consumer scrap, in a single heat cycle.

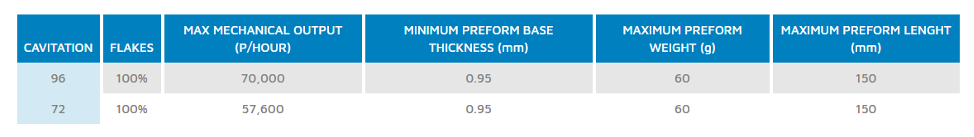

The system can produce over 300 million containers per year.

“This is a solution that represents the perfect response to the requirements of the new circular economy,” says Gianfranco Zoppas, President of SIPA parent company Zoppas Industries.

“Waste reprocessing is rendered sustainable and economical while producing new products of the highest quality."

This innovative technology uses 30% less electricity than traditional recycling processes, thanks largely to systems integration, while CO2 emissions are cut by 25% – a massive 60% when you compare it to bottle production from virgin resin.

READ ALSO: "Case History: first platform for lightweight PET preforms"