SIPA’s history in the field of machines for the production of PET containers began in 1986 and since then has focused on innovation and quality.

With over thirty years of experience in this field, today the company can take up any challenge in the production of preforms and bottles.

Creativity is an increasingly important element to design packaging that stands out on supermarket shelves and among e-commerce pages. To design attractive and functional bottles, SIPA design is entrusted to teams of designers and technicians.

Let's see the fundamental steps that go from the study of the project to the development of an idea that meets the customer's requests.

The analyses at the base of the development of PET packaging

Our specialists deal with the projects starting from an accurate study useful to bring out critical issues and peculiar characteristics of the packaging they have to design.

The areas of our indepth analyzes are:

- The market in which the product is to be placed and, consequently, the container

- The objectives of the packaging and the product it contains

- The production environment in which the container will be made

The information collected becomes the foundation on which to build the design of a packaging able to highlight the characteristics of the product and the brand, but also that can be produced simply and quickly.

Guidelines of the design: creative and technical aspects of the PET bottle

The creative process in SIPA is always accompanied by a technical evaluation of the PET bottle project, so as to create designs capable of striking the attention of end consumers, but also designed for rational and efficient production and logistics.

Some factors that are considered during the packaging design phase concern both aesthetic and marketing aspects, as well as elements that affect safety and costs, for example:

- Innovative shapes study

- Dimensions suitable for the product and the reference market

- Message that the brand wants to communicate

- Container performance

- Container lightweighting

- Correct blowability

- Characteristics of the machines (blowers, fillers, cappers, conveyors)

- Simple and safe palletizing

- Resistance to vertical load and dynamic transport

- Energy saving solutions for the production of preforms and bottles

Our designers always combine creativity and technical knowledge to ensure the development of safe and advantageous PET bottles from the point of view of production.

Technical Study: "WATER BOTTLES PACKAGING: CREATIVITY FOR TODAY'S MARKET"

Technical Study: "YOGURT PRODUCT PACKAGING DESIGN: CREATIVITY BECOMES FUNDAMENTAL"

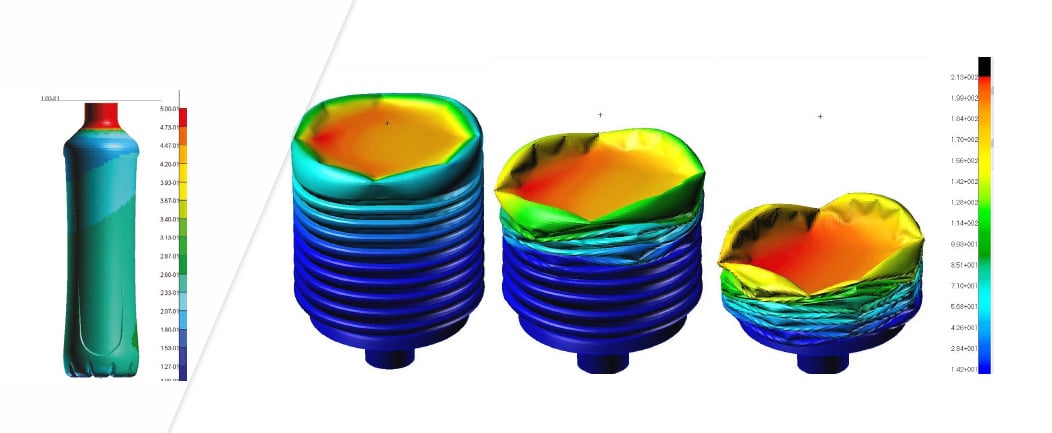

FEA analysis before making samples

Through the computerized analysis of finite elements, FEA system, SIPA specialists evaluate the feasibility of the packaging without having to move on to the real production of samples to be tested and verified.

This virtual process allows you to determine if there is a need to optimize the design of the container to comply with aimed characteristics at design stage.

In addition, FEA analysis allows you to evaluate how and how much it is possible to lightweight your PET packaging, so as to reduce operating costs without running any risks due to the loss of functional characteristics.

If you are looking for a reliable partner for the development of innovative and advantageous PET packaging, rely on SIPA designers and technicians.