Packaging is an extremely relevant component to the marketing of products.

It combines different functions in terms of containment, protection, transportation, besides the accessibility aspects, since packaging serves as a connecting and interaction component between product and end-user.

From this perspective, PET is a light, economic and safe material for the environment without sacrificing the features of transparency, ease of handling and personalization in marketing.

The PET Packaging Market is forecast to reach 21.2 million tonnes by 2021, according to a report by Smithers.

In 2015, PET packaging amounted to just under 16.7 million tonnes, representing a 3.8% increase on 2014 levels, go further falls in PET resin prices are also projected to benefit the market.

Why producers are increasingly geared to PET?

Suppliers in our extensive industry data base, especially Food, Household Cleaners, Personal Care and Cosmetic focus increasingly on PET for packaging in relation to the benefits available:

- COST-EFFECTIVE: A few examples of the economic advantages of PET: lower costs in terms of raw materials, lower processing costs thanks to more simplified, faster and more efficient processes, lower transport costs thanks to its lightness.

Read Also: "PET bottles vs glass and cans: costs and benefits working with PET"

- RESISTANT: Thanks to its composition, PET is resistant against shock, unbreakable and safe throughout its life cycle: this ensures safety during production, transport and use by the end user.

- SAFE PET: ensures unrivaled hygiene standards and preserves the organoleptic and nutritional properties of each type of food or beverage.

- LIGHT PET: is characterized by extreme lightness compared to other materials used for bottling and, more specifically, for packaging. It is easily shipped to end users, but also ensures significant savings in terms of transportation costs from the production site to the point of sale.

- CUSTOMISED containers can now be developed in different shapes, colours, decorations and barrier properties thanks to PET with reasonable prices.

- RECYCLABLE PET is 100% recyclable and, when recycled, it can give life to new containers, but also to other products used in everyday life.

Read Also: "From used to new 100% rPET bottles: SIPA Xtreme Renew"

PET packaging material usage, collecting and recycling data

For the above reasons, PET material is increasingly used for a number of industries.

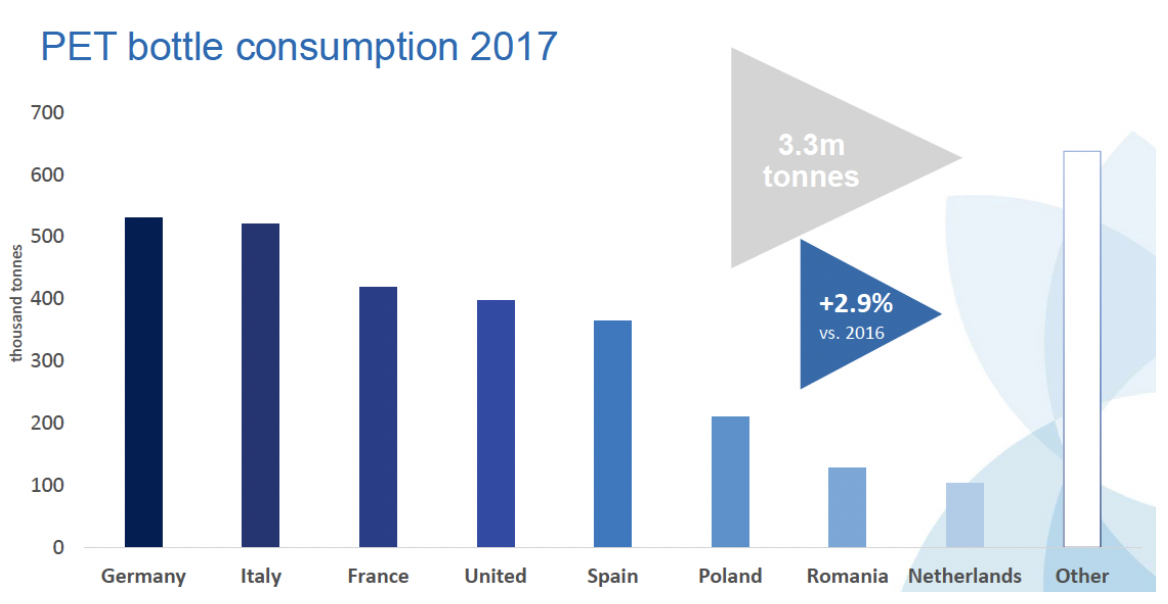

The chart above shows the overall volumes placed on the European market in 2017, the year that marks a + 2.9% compared to 2016 (Source: ICIS).

While PET usage is growing, there are, as a result of which, problems related to environmental protection.

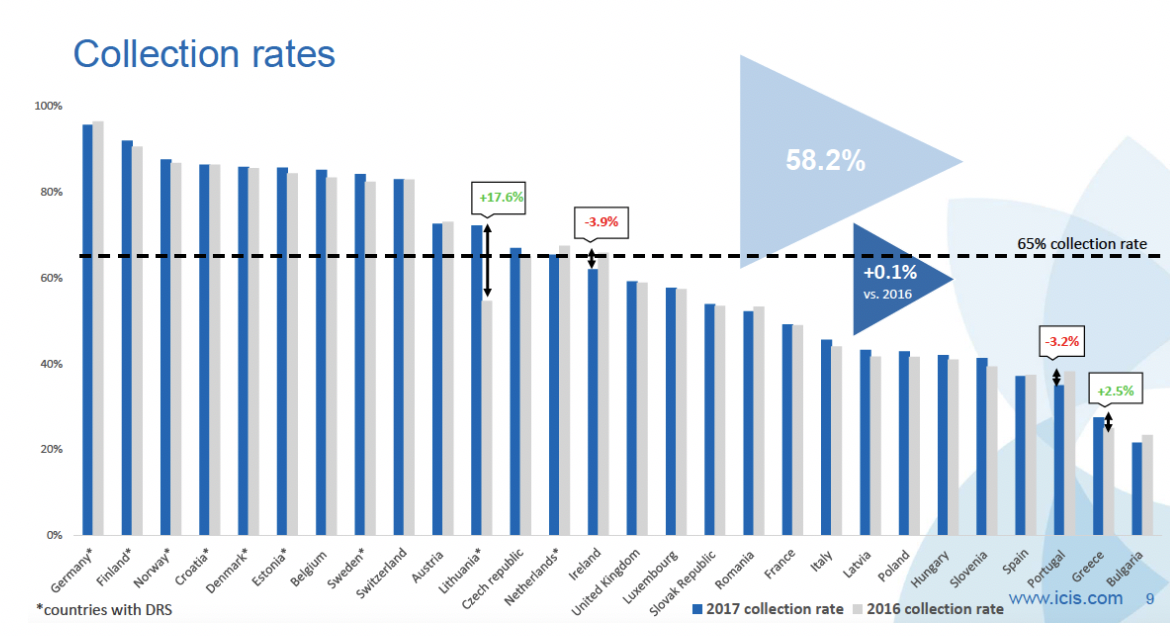

Analysing the collected data, always at European level, it appears that there were no significant collecting plastic gains in 2016-2017, despite the wider dissemination of PET.

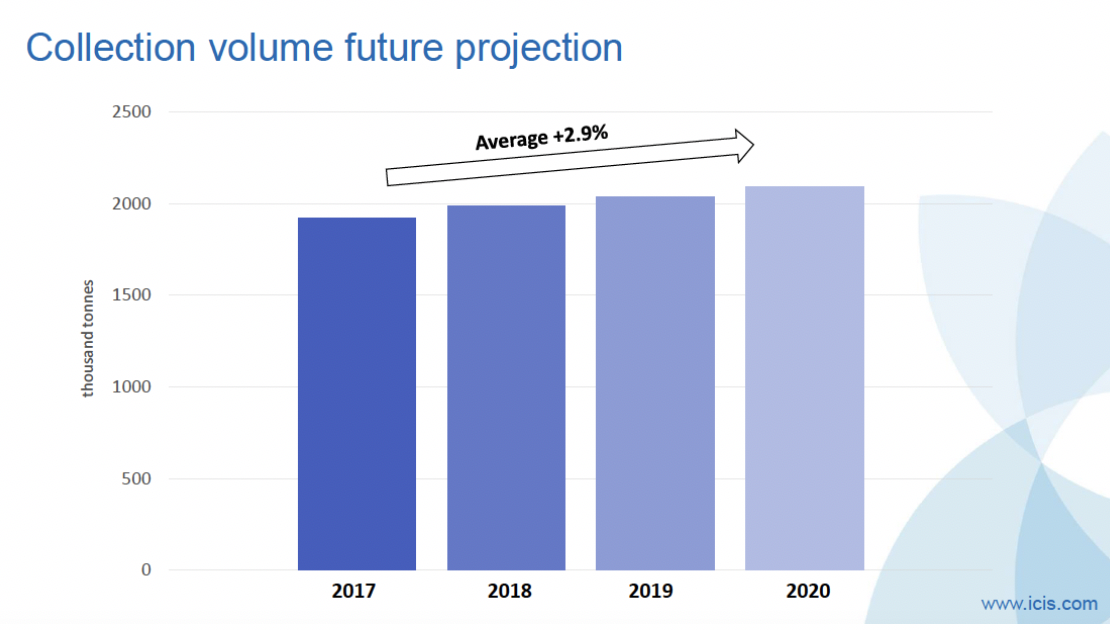

Collection estimates are foreseen in the coming years, due to a greater sensitivity of the consumers, combined with a more timely organisation of recycling in different countries, with average increase expected to grow by nearly 3%.

Lightweighting policies from companies who use PET packaging material

Faced with this data, manufacturers are responding with sustainability-oriented policies.

The plastic sector faces strong challenges in regards to sustainability. However, it is the recycling streams and the development of these that will help neutralize such sustainability issues.

Recycling rates have been improving gradually in Europe, but consumer behaviour is likely to prevent a fully sustainable material.

Nevertheless, sustainability will play an increasingly prominent part in the market going forward. Recycling streams are still largely underdeveloped, even in mature markets

Some of the main market trends put into practice by an increasing number of companies concern intensive efforts on the progressive PET packaging lightweighting and bottle-to-bottle recycling.

The trend towards lightweight products is partially as a result of cost-optimisation and helps manufacturers achieve a competitive edge.

Since the beginning of 2000, the weight of a 0.5 L bottle of water (16.9 oz) has halved. Technological improvements allowed for a reduction in costs and contributed to a more positive environmental impact.

Lowering preform weights by as much as 20-30% in a constant effort to improve profit margins, container manufacturers continued to push the limits of how light a given bottle can be without compromising its performance.

PET resin costs are the most significant contributor to the cost of producing a package. A 5% reduction in part weight can return a 4.4% savings to the cost of the product.

Comparatively, a 5% equipment cost reduction will yield a 0.26% saving on the cost of the product.

PET developments: solutions offered by manufacturers

The companies involved in design, engineering and manufacturing of PET containers are studying new permanent solutions in terms of sustainability, by reducing the packaging weight.

This is primarily concerned with preform and container symbiotic design, with lightweight packaging, offering, among others, the advantage of lower costs per bottle.

More broadly, the PET packaging-related sustainability projects take into considerations these following stages:

Preforms

- Study and engineering of preforms design

- Choice of material (Virgin, rPET, biomass based on mechanical values)

- Lightweighting (base and package)

- Preform shape optimization (stretch ratios)

Bottles

- Bottle design: attractive forms, new marketing ideas

- Blowing molds for bottles

- Packaging engineering for better performance

- Lightweighting studies

Prototyping

- Structural calculations and simulations

- Sampling preforms or bottles packaging development

- Lab performance evaluation of packaging and qualification

Production

- Injection and blowing molds engineering

- Molding production

- Analysis of packaging behaviour on the bottling line