Within the PET preform production process, the life of the mould is an important factor that has a considerable influence on the return on investment for a company.

When bearing in mind the fact that the mould will be used for a long time, it is advantageous to include options to make the product more durable when drawing up the purchase agreement.

Monitoring the state of moulds, carrying out timely maintenance and selecting refurbishment services are procedures that make the working life of moulds longer, generating profits for the companies that produce PET preforms and containers.

READ ALSO: "Refurbishment centers: strong support for customers around the world"

In the following paragraphs we will look at the factors that determine mould productivity and the options that allow it to be used for a long time.

Doubling the lift of a PET preform mould

The “state of health” of a mould can be measured indirectly from the size of the flashes on the preform.

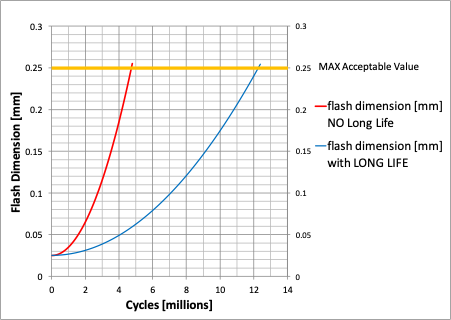

Typically, the behaviour of a mould in terms of wear is as described in figure 2, which shows both the progression for conventional moulds and for moulds with Sipa’s Long Life system.

As can be seen from the graph, it is possible to extend the working life of the moulds enormously by applying specific treatments.

Solutions such as Long Life by Sipa can double and sometimes even triple the working lift of mould components that are subject to wear, that is to say the stacks (the moulding components).

Applying special coatings to the stacks, to give the surfaces subject to wear (tapers) improved characteristics that increase their hardness and reduce the friction coefficient, result in an exponential increase in working life.

The technological details that make the mould more efficient and durable

The benefits of the Long Life system obtained by applying the features described above are completed by using the half mould pre-alignment systems.

Making use of a line type pre-alignment system guarantees the coupling precision of the half moulds on every cycle, with a consequent reduction in stress in the components subject to wear (tapers).

In practical terms all this gives an additional noticeable advantage in terms of working life of the components involved.

Injection mould inspections and refurbishment

When the moulds are inspected methodically it is quickly possible to identify the parts that are not working perfectly and are causing a reduction in PET preform production process efficiency.

Through this inspection service it is possible to proceed with all necessary maintenance and all the operations that will increase the overall life of the injection moulds.

Finally, refurbishment of the PET preform moulds allows optimisation of the costs sustained to purchase these essential elements.

READ ALSO: "What do the economic benefits of an injection mould depend on?"

Sipa provides its customers with three flexible programs for regeneration of hot channels:

- Basic, providing routine maintenance

- Intermediate regeneration

- Full regeneration (refurbishment)

Relying on a well established company that is able to provide all these services to extend the lifespan of PET preform injection moulds means you can maintain high quality in products and, at the same time, achieve a saving in costs.

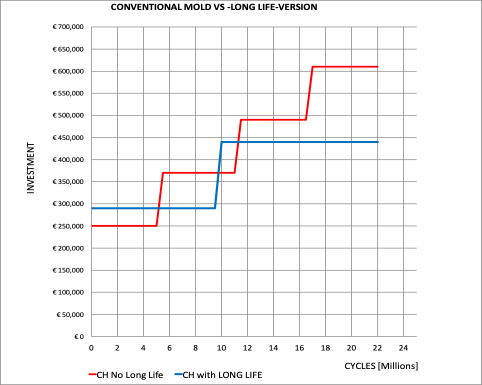

The saving generated by Sipa Long Life: a concrete example

Example for mould (Cold Half) 72 cav (50x140)

Investment in mould (No Long Life): €250,000

Long Life: €40,000

Investment in mould (with Long Life): €290,000

Mould refurbishment (No Long Life): €120,000

Mould refurbishment (with Long Life): €160,000

Mould used for 22 million cycles

Case 1 (No Long Life):

Initial investment: €250,000

Refurbishment required every 5.5 million cycles maximum (at 5.5 million, at 11 million, at 16.5 million) => total No. 3 refurbishment operations costing 120,000€ each, total 360,000€.

Overall investment= 250,000+360,000€= 610,000€

Case 2 (With Long Life):

Initial investment: €280,000

Refurbishment required every 11 million cycles (at 11 million) => total No. 1 refurbishment operation costing €160,000.

Overall investment= 280,000€+150,000= 440,000€

Saving= €170,000

Considering a production of 7,000 hours/year with a cycle time of 6 seconds (=600 cycles/hour), 22 million cycles are carried out in 5 years (4.2 million/year), payback is achieved after the first year.

READ ALSO: "The advantages of SIPA refurbishment for Mpact in South Africa"