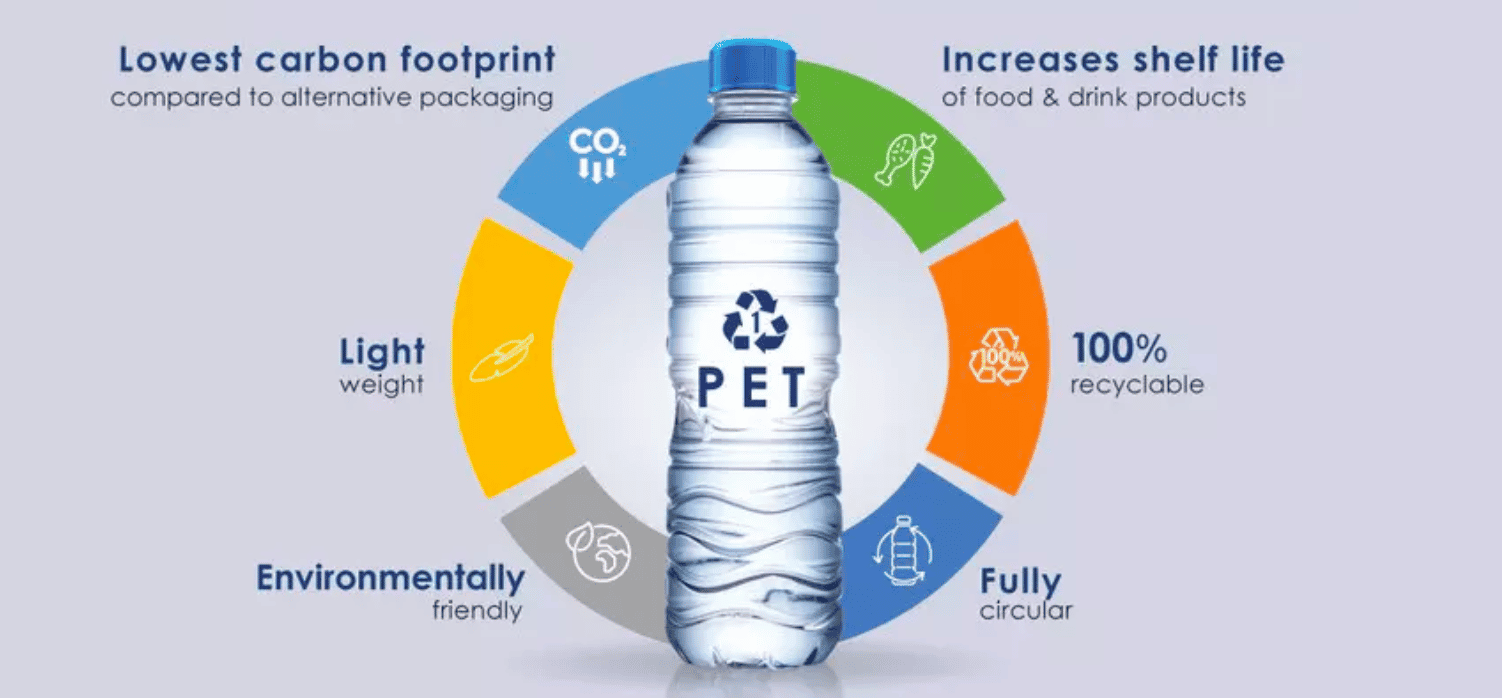

Over the years, polyethylene terephthalate (PET) has seen a net increase at industrial level, particularly in the field of packaging for various types of edible and non-edible liquids, becoming one of the most widely used thermoplastic polymers in the world.

This is all thanks to an excellent balance of thermal and mechanical properties, combined with low production cost levels.

Read Also: "PET bottles vs glass and cans: costs and benefits working with PET"

The reasons for the spread of PET

How is PET used within the market?

The main uses are the fibres market (60%), Food and Beverage packaging (30%), bioriented films (5%) and, to a very marginal extent, high-tech applications.

Its wide use within the Beverage sector is due, in particular, to the characteristics of this material, such as its excellent barrier function to gas, aromas, resistance to flavor scalping, along with its transparency and excellent processing.

These characteristics have allowed rapid spread of the use of PET as an ideal material for a wide range of products, such as carbonated drinks, fruit juices, tea, mineral water, edible oil, milk and dairy products.

Read Also: "The spread of most suitable types of yoghurt drinks packaging"

Containers in polyethylene terephthalate (PET) have quickly conquered the market, passing other traditional materials, starting with glass.

Hygiene in the various phases of the packaging process

Among the various strong points offered by PET, particular attention must be given to those relating to hygiene during the various phases involved in creating the containers, in particular those for the Food and Drink sector.

The injection phase, within the preform production process, is made up of three essential steps: filling, maintenance and cooling.

During the filling phase the molten PET passes through a hot chamber and is injected, through a heated nozzle, into the cold mould.

On coming into contact with the cold mould a first part of the material solidifies immediately, producing what is known as the solid sheath.

During this phase there is no danger of bacteria being present because the procedure takes place at a temperature of approximately 260°.

During the stretching blowing process, the preform is heated using lamps that emit infra-red light at temperatures exceeding Tg (90°÷120°) to allow stretching and blowing.

Process hygiene: the differences between single-stage and two-stage solutions

The level of hygiene in the entire process changes greatly in single-stage and two-stage solutions. The former are designed to carry out in single cycle, so using a single machine, the whole of the injection and stretching/blowing ISBM (Injection Stretch Blow Molding) process.

Technical Study: "Producing polystyrene bottle packaging using ISBM lines? Yes we can!"

The extruder is used to inject the melted material into the injection mould to shape the preform, which is then partially cooled and, passing through a conditioning station to optimise the thermal profile in the sub-neck above all, is positioned inside a blow mould which will give it its final shape.

The preforms and, subsequently, the bottles, never leave the cabin, so - because they are not subject to any human intervention - the environment is intrinsically clean, with a low risk of contamination.

The process is different for two-stage solutions, in which various machines work together: an injection press produces the preforms which leave the machine cooled and which, at a subsequent time, are transferred to another machine that blows the bottle.