Since we are living in a world where our bodies are unknowingly exposed to many and different types of ailments, it becomes extremely important for every family to cook using edible oils to eliminate the chances of any health risk.

These products have outstanding attributes.

A key factor to consider when talking about edible oils is their packaging: when you closely observe them, you wonder how challenging it should be for the manufacturers to deal with them.

How do they send to customers thousands of litres of edible oil adequately bundled in those colourful bottles?

How do they make sure that the oil reaches your home in complete safety?

Before answering these questions, let's focus on those features that make edible oils so much preferable and discover why their packaging has to be user-sensitive.

Factors that could affect the quality of the oil

First of all, the packaging factors that could affect the quality of the oil should be analysed.

We are referring to:

- The light that passes through the packaging which, being a source of energy, activates the oxidation process

- The presence of oxygen in the head space of the packaging that comes in contact with the product

- Autocatalytic oxidation

- The temperature and level of humidity during the storage phase

- The transfer of substances from the packaging to the oil

- Fragrances/odours passing through the sides packaging walls

Criteria for choosing packaging materials for edible oil

Edible oil companies must carefully choose the most suitable packaging in order to ensure the correct storage of their product.

The right packaging must therefore prevent:

- the loss of the flavour or acidity of the product

- the filtering of light which may result in the oil turning rancid

- the oxidation of the oil with a consequent loss of flavour

- the absorption of odours

And that’s not all. There are also other factors which, as well as protecting the edible oil, can also influence sales.

We are talking about leak-proof packaging, the price of materials (in terms of direct costs and transport costs), branding and customisation.

Trend Analysis: "PET packaging material: market trends and lightweighting factor"

Micro-categories of edible oil bottle packaging

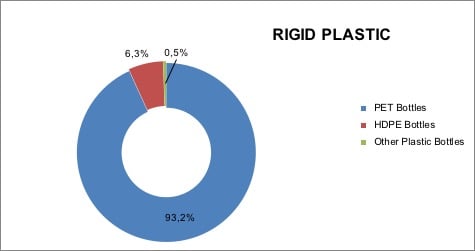

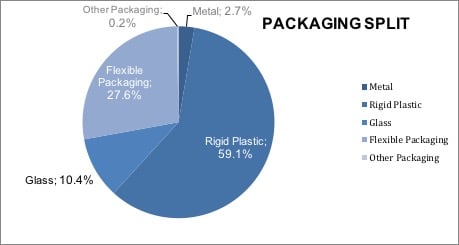

As mentioned, the nature of the material has an influence on the quality of the oil. We can divide the types of edible oil packaging into macro-categories:

- Rigid packaging: HDPE, Tin, Glass, PET

- Flexible packaging: Plastic pouches, Stand-up pouches

- Semi-rigid packaging: Liquid cartons, Bag-in-box

READ ALSO: "PET BOTTLE FOR EDIBLE OIL"

The reasons for paying maximum attention to edible oil bottle packaging

We believe it is useful to summarise the characteristics that good quality packaging should have in order to meet various types of requirements:

Product

The ideal packaging is able to offer the best guarantees in terms of protection, cleanliness as well as product freshness.

Distribution

The best packaging meets the need for lower costs and better logistics.

Packing

In order to optimise sales it is important to pay the utmost attention to the attractiveness of the packaging and its ability to be displayed, the possibility of branding it, and the modularity of the sizes, from the smallest to the largest.

Read Also: "PET bottle design for edible oil: creativity and benefits"

Marketing

From a marketing point of view the packaging must ensure maximum visibility and the right level of affordability, guaranteeing quality and attributing the right degree of value to the product.

PET: the most effective packaging material

For many years, PET has been the preferred packaging material for bottling water and carbonated soft drinks.

Successfully in use for over 40 years in packaging food and beverage products, it has recently been increasingly adopted also for liquid dairy products, beer, and other food products, such as ketchup.

PET has numerous qualities:

- it's shatterproof and ensures product integrity;

- it maintains great taste;

- it offers a premium look and feel;

- it creates a more convenient experience for the consumer;

- it provides significant cost and environmental benefits in the production and supply process.

These are the features consumers are looking for today. Thanks to these characteristics, the benefits of this material are also recognised by producers of edible oils, and this is the reason why the transition from glass and other materials to PET looks set to continue.

From sourcing raw materials through to quality control, refining, blending, and packaging, food safety is the most important consideration in what we do as a business.

When packaging is in direct contact with its contents, it needs to meet the very highest standards of product quality and safety. Both shelf life and consumer expectations of the finished product play a key role in the choice of the material.

The packaging development process of PET includes the analysis of how the oils performed when packaged in PET, simulating the environmental conditions to which the product would be subjected throughout the supply chain in the company's dedicated laboratories.

Packaging manufacturers focused on the effects of light, oxygen, and temperature on the oils and considered factors such as viscosity, density, and surface tension. Moreover, in analysing the liquid-package interaction, they also evaluated the effect that the filling temperature has in terms of variation of the volume of the edible oils.

PET is a biologically inert plastic, with well-defined constituent materials and no additives required for enhanced performance: for this reason, it has been fully approved for food and drug use by all official food safety organisations, including the US Food and Drug Administration (FDA) and European Food Safety Authority (EFSA).

Summing up, PET has revolutionised the packaging market in recent years offering solutions that meet practically all the needs of producers, also in the edible oil segment.

It is approved as food contact grade all over the world. Safety also includes mechanical resistance, also during transportation.

Costing less than traditional materials, PET is convenient from a supply costs perspective and is also light, a factor that has a notable impact on transport costs.

In terms of sustainability, PET is 100% recyclable. rPET, made from recycled packaging, is also becoming increasingly popular and ensures savings in terms of virgin materials.

Finally, its versatility gives manufacturers maximum scope in terms of shapes, sizes and customisations when marketing their products.

Popularity of different types of packaging