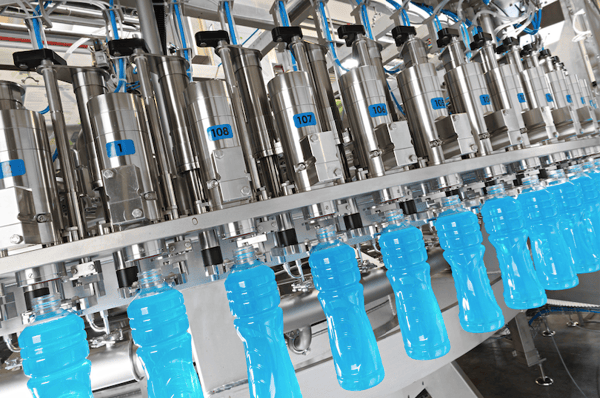

Technological innovation has led to the development of increasingly evolved liquid filling machines, offering a progressively better performance.

All the monoblocks are designed to ensure great operating flexibility, high levels of efficiency and a drastic decrease in format change over times.

A lot of attention was also paid to the sanitizability of all the component involved in the filling techniques and process.

READ ALSO: "PET BOTTLE FOR EDIBLE OIL"

In this article we will see in detail some of the most efficient types both in terms of precision and production speed.

We will talk about:

- Electronic and volumetric filling monoblocks with contact valve

- Electronic and gravity filling monoblocks with no contact valve

PET bottle filling machine:

electronic and volumetric filling monoblocks with contact valve

We first examine the isobaric volumetric electronic filler for the bottling of still and carbonated products in PET bottles.

It is one of the most innovative solutions on the market today.

These PET bottle filling machines offer a complete range for various products to be processed; they are fitted with an extremely flexible contact valve. This is particularly useful for those bottlers who need to processed still, carbonated and hot fill products on the same line.

The speed depends on the valve configuration and the product to fill. The product contained in the bottle is defined by using a magnetic flow meter, which therefore ensures a high filling precision.

There is no vent tube: deflection takes place with a swirl system that significantly reduces foam from forming.

Both the traditional configuration with the central tank and the direct connection with the mixer (xfill version) are available: the buffer tank of the mixer is used as the tank of the filler. This innovative solution means various operating advantages that optimise the filling process and a reduction in the related costs.

These machines feature a high level of attention to cleaning and sanitizability of the various components, with solutions that notably reduce the risks of contamination (automatic dummy bottles, separate return of air, draining base, etc).

Read Also: "Advantages of PET bottling lines:cleanliness, flexibility, lower costs"

The great operating flexibility of the valves allows the creation of multi-product lines, also CSD/Hot Fill. In addition these extremely clean valves are ideal for the monoblock configuration for cold filling in Ultra Clean conditions of sensitive products such as fruit juice and CSD with no preservatives, milks and derivatives, etc.

In this case the monoblock will be fitted with an ISO 7 microbiological isolator, reducing the clean filling area around the container, automatic cleaning of the environment (COP), HEPA filters, a cap sterilisation system and a steriliser of the containers for the solutions not in Sincro Bloc.

Filling speed from 10,000 to 36,000 b/hour on 1.5 l with CSD (13°C), fillers from 50 to 180 valves.

The simpler gravity version is also available. These machines are fitted with filling valves with valve pin, with contact between the valve and the bottle, and dual speed. It is an extremely versatile valve for hot and cold filling with still or pulp products (also large sizes).

This solution ensures optimised hot product filling cycle and “mouth rim” filling.

Filling speed from 10,000 to 42,000 b/hour on 1.5 l with fruit juice (85°C) for fillers from 50 to 180 valves.

PET bottle filling machine:

electronic and gravity filling monoblocks with no contact valve

The electronic gravity volumetric fillers, again for PET bottles, in the configuration for water, milk, homogenized juices and still products, are equipped with an extremely simple, clean and fast filling valve, without any contact between the valve and the bottle. This filling valve features a membrane valve that manages the dual filling speed and high flow performance.

The valve has a magnetic flow meter for a very precise definition of the bottle’s content.

Models of PET bottle filling machines also exist that are fitted with a special dual speed “no contact” filling valve with shutter, ideal when particular hygienic conditions are required. Also for this variant the valve has a magnetic flow meter to define the bottle’s content.

Read Also: "Edible oil bottle filling machines: quality, reliability, productivity"

These are machines designed for HF applications in an Ultra Clean configuration.

The cleaning features of the valve and the configuration of the monoblock make them particularly suitable for the hot and cold filling of sensitive products such as premium fruit juices with pulp (not homogenized) also for large sizes.

A different concept concerns the electronic weight fillers, which feature a 3-position membrane valve with dual speed. This solution ensures high flow performance combined with excellent precision and accuracy of the bottle’s content, which is measured through a load cell.

It is an ideal configuration for high added value products such as edible oil, milk, premium clear juices, home and personal care products.

These filler models range from 20 to 180 valves (up to 96 for the weighted ones), with filling speeds that range, based on the type of valve and product to be processed, from 8,000 to 60,000 b/hour on 1.5 l with still water (ambient temperature).