During recent years, sustainability has taken on an increasingly significant role, both in terms of a progressive decrease in emissions from industrial...

Blog listing page

Advantages of PET bottling lines:cleanliness, flexibility, lower costs

As has been seen, integrated lines, starting from the most widely used, that is to say systems made up of blower/filler/capper, are able to offer...

All the advantages of integrated bottling lines in the PET sector

Integrated PET bottling lines, with more machines directly connected or combined together, are a solution that is increasingly used by companies, as it...

Optimization of mould manufacturing times thanks to Lean Manufacturing

For some years now, the concepts of Lean Production and Lean Manufacturing have been introduced to all the most sophisticated world production systems.

Injection mold refurbishment: SIPA longer life and better performance

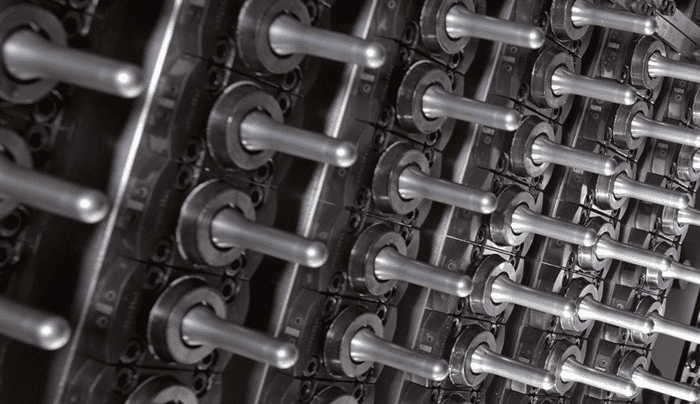

Maintenance is an essential aspect with regard to moulds and their ability to respond to production needs over time.

Refurbishment centers: strong support for customers around the world

SIPA operates mold refurbishing centers in Vittorio Veneto, Atlanta, Los Angeles, São Paulo, and San Luis Potosi, Mexico. In the next few months, the...

Injection moulds: integration with pre-existing systems and machinery

In this article we discuss a subject that is on trend and of particular interest for converters and bottlers, that is to say the ability to integrate...

What do the economic benefits of an injection mould depend on?

When purchasing an injection mould for the production of PET preforms or when replacing it, we find ourselves faced with a multitude of different offers....

The advantages of SIPA refurbishment for Mpact in South Africa

SIPA technology means it is possible to simplify and optimise production in companies working in the field of PET bottling.