SIPA’s new XFORM GEN4 XP system incorporates the latest generation of preform injection molding technology to deliver the lowest conversion cost...

Blog listing page

Injection moulds: integration with pre-existing systems and machinery

In this article we discuss a subject that is on trend and of particular interest for converters and bottlers, that is to say the ability to integrate...

What do the economic benefits of an injection mould depend on?

When purchasing an injection mould for the production of PET preforms or when replacing it, we find ourselves faced with a multitude of different offers....

Injection moulding process: customisation, flexibility & maintenance

The companies that produce injection moulds for PET bottling plants provide very different products and services. In this article we intend to summarise...

The advantages of SIPA refurbishment for Mpact in South Africa

SIPA technology means it is possible to simplify and optimise production in companies working in the field of PET bottling.

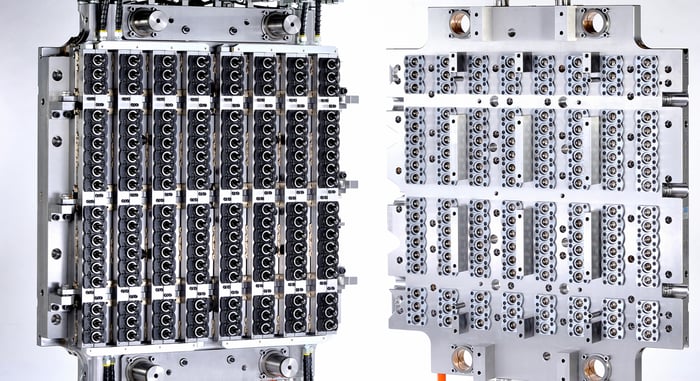

Hot runner mould system & operating costs: alignment and cleaning

An efficient mould is a goal to achieve in order to maximise efficiency in companies that produce PET preforms, decreasing operating costs.

For this...

PET Manufacturers: some advantages of mould and preform machines

In the production of PET preforms, bottles and containers every company has specific needs that must be satisfied by those supplying the machines and...

RPET plastic preforms and containers: problems and solutions

Growing public attention to plastic pollution is making consumers turn towards packaging made from recycled material.

PET preform system: technology and quality of a PET injection mould

Purchasing a mould is undoubtedly a considerable investment for companies who produce PET preforms, and also for those industries manufacturing...

How to select PET preform injection moulds

When purchasing a moulds for PET preforms you realise that there are various companies who can supply them and the choice is not that simple.