As has been seen, integrated lines, starting from the most widely used, that is to say systems made up of blower/filler/capper, are able to offer...

Blog listing page

All the advantages of integrated bottling lines in the PET sector

Integrated PET bottling lines, with more machines directly connected or combined together, are a solution that is increasingly used by companies, as it...

Optimization of mould manufacturing times thanks to Lean Manufacturing

For some years now, the concepts of Lean Production and Lean Manufacturing have been introduced to all the most sophisticated world production systems.

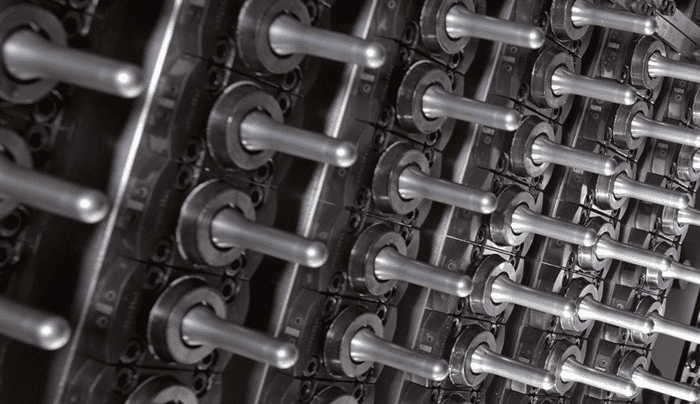

Injection mold refurbishment: SIPA longer life and better performance

Maintenance is an essential aspect with regard to moulds and their ability to respond to production needs over time.

PET bottle machine for edible oil: after-sales and lifecycle services

In the context of PET packaging, being able to count on a partner able to solve any kind of problem that can occur while using bottling machines...

The leading players who use PET containers anticipated SUP Directive

Directive on Single-Use Plastics (SUP) has entered into force; a measure intended to revolutionise plastic market with a significant bearing, in...

Lowering the cost of PET preform production while maintaining the same quality

Trying to reduce production costs while keeping standard of quality high is the best way of increasing company profits. This also applies to the...

PET packaging: alternative materials for virgin PET

Today we are highly aware of the damage that is being done to the planet because of the irresponsible disposal of used plastics packaging. It ends up on...

Refurbishment centers: strong support for customers around the world

SIPA operates mold refurbishing centers in Vittorio Veneto, Atlanta, Los Angeles, São Paulo, and San Luis Potosi, Mexico. In the next few months, the...