What could be more indispensable and simple than water, probably nothing. Yet marketing water is not so easy, because there are many competitors on the...

Blog listing page

What role does creativity play in large size water packaging?

When you think about the design of a large size for water packaging you imagine that functionality has a much more relevant role than creativity, but...

rPET production, solutions that combine sustainability & productivity

The principles of sustainability regard increasingly broad market sectors at a global level, involving end users and, as a consequence, also large brands...

New frontiers of packaging: co-polyester and expanded polystyrene containers for liquids

In a sector like that of packaging for beverages, still or carbonated, innovation is seeing continual progress, not only thanks to new concept machines,...

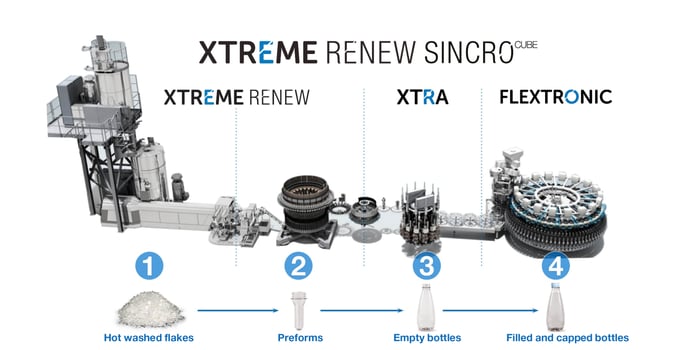

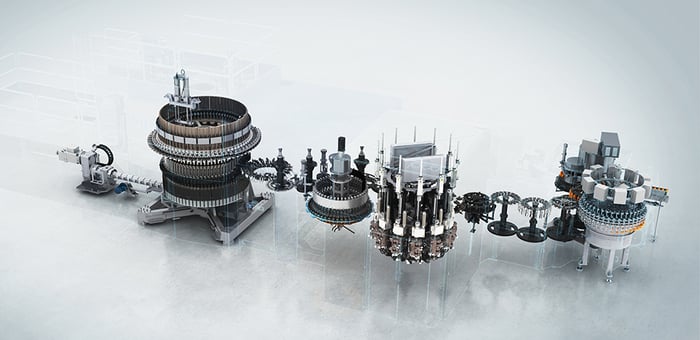

All in one: preform production, blower, rotary fillers/cappers machine

The whole value of Xtreme emerges in the integrated Sincro Cube line, a unique solution made possible by SIPA technology.

How integrate linear blower, rotary filler and capper in PET bottling

SIPA is working non-stop to identify unique solutions that will satisfy the needs of manufacturing companies with regards to complete PET bottle...

Advantages of XTRA rotary blowing machine combined with rPET preform

Within the context of PET bottling lines, SIPA technology has created XTREME RENEW SINCRO CUBE, that is to say the integration of an...

Tritan bottles production process: requirements and optimisation

Having ascertained how important Tritan is today, estimates indicate a very high increase in this material in future years.

Pushing its spread, on the...

New systems integrating the production of preforms with bottling lines: Xtreme Sincro

Among the big players on the PET bottling market, SIPA is the only one to have further expanded the concept of integrated lines and taking advantage of...

PET bottle packaging machine: hygiene and differences between single and two-stage

Over the years, polyethylene terephthalate (PET) has seen a net increase at industrial level, particularly in the field of packaging for various types...